“As the calendar flips to another year, it’s the perfect time to reflect on the past, set new goals, and explore fresh opportunities.”

If you’re involved in the world of construction, manufacturing, or engineering, 2024 holds incredible potential for innovative projects using steel and aluminium. At ShapeCUT, we’re excited to usher in the new year with a host of possibilities in steel and aluminium profile cutting, beveling, drilling, machining, rolling, stud welding, and aluminium processing. Let’s dive into the exciting prospects that await in the world of metals and manufacturing.

Exploring the Possibilities

2024 brings with it the promise of new beginnings, and what better way to embrace it than by embarking on transformative steel and aluminium projects? Whether you’re a seasoned professional or just getting started in the industry, there’s always room for innovation and growth. ShapeCUT, a trusted name in the metal processing industry, is here to guide you through your journey of turning possibilities into reality.

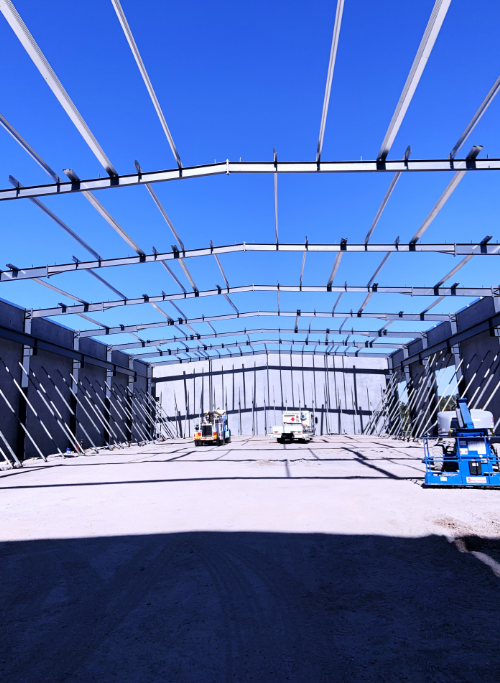

Imagine designing and constructing awe-inspiring architectural marvels that stand the test of time. Steel and aluminium’s durability, versatility, and aesthetic appeal make them the ideal choice for modern buildings, bridges, and landmarks.

Architectural Marvels

Floating Steel Structures for Modern Homes: One of the innovative trends in residential architecture is the use of steel to create the illusion of floating structures. Architects are utilizing steel framing and support systems to design houses that seem to defy gravity. Large cantilevered sections of the building appear to float above the ground, creating a striking visual effect and allows for open and spacious living areas.

Aluminium-Clad Facades: Aluminium is increasingly being used to clad building facades, providing architects with a versatile and lightweight material that can be customized to achieve various visual effects. The use of aluminium also contributes to energy efficiency, as it can be coated with reflective finishes to reduce heat absorption and lower cooling costs. This innovative use of aluminium makes it more sustainable and energy-efficient.

Steel and Glass Combinations for Iconic Landmarks: Some of the world’s most iconic landmarks are now featuring steel and glass combinations in their designs. This trend combines the strength and durability of steel with the transparency and elegance of glass to create breathtaking architectural wonders. For example, steel frameworks support extensive glass panels to construct observation decks, skywalks, or viewing platforms in tall buildings and bridges.

Sustainable Solutions

With the global shift towards sustainability, steel and aluminium play a pivotal role in creating eco-friendly solutions. Explore projects focused on renewable energy, electric vehicles, and sustainable infrastructure to contribute to a greener future.

In 2024, the steel and aluminium profile cutting and shaping industry is embracing a holistic approach to sustainability. Beyond just eco-friendly materials, businesses are now incorporating sustainability into every aspect of operations, from production processes to waste management and energy consumption.

By adopting these comprehensive sustainability trend the industry is not only committed to using environmentally friendly solutions but also optimizing the production processes to minimize waste and reduce energy consumption. The ultimate goal is to create a closed-loop system where materials are efficiently utilized and any waste is recycled or repurposed.

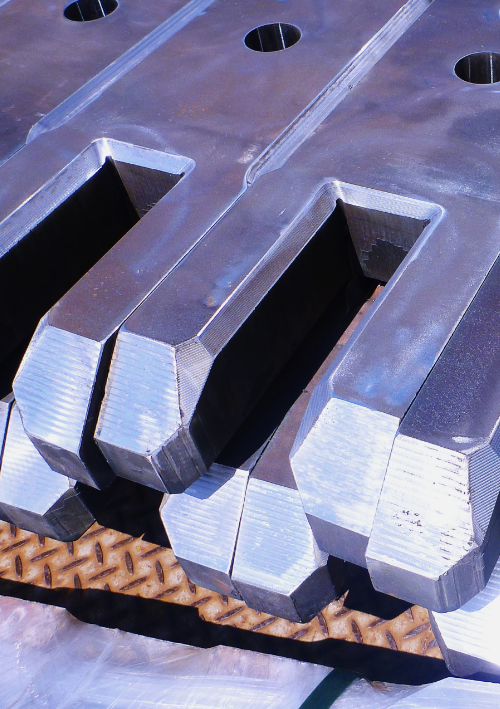

Industrial Advancements

Revamp your manufacturing processes by integrating steel and aluminium components. Precision cutting, drilling, and machining services from ShapeCUT can help you optimize your production lines for efficiency and quality. ShapeCUT is one of Australia’s leading providers of high precision steel & aluminium profile cutting and metal processing with 15+ cutting machines, and some of the largest cutting beds in Queensland.

Having been in the business since 1994, we know on-time delivery is crucial and that comes down to the machines on the floor and their operators. That’s why we’ve expanded our facilities in Brisbane to accommodate the widest range of quality plate steel & aluminium to fed our top-of-the-line plasma, laser, oxy and router cutting machines. With additional services like drilling, tapping, bending, bevelling and more for a complete steel processing service with the highest precision and quality.

We are quality assured with ISO 9001:2015 accreditation and have memberships with the Australian Industry Group and Australian Institute of Steel. For profile cutting delivered with precision, reliability and speed, contact ShapeCUT today to get a fast, competitive quote.

Marine Innovations

The marine industry is constantly evolving, and 2024 presents opportunities to participate in cutting-edge boat kits and sea vessel projects. Our stud welding and machining capabilities can meet the stringent demands of marine engineering.

Our purpose built aluminium cutting facility is ready for you including the marine, transport, and aviation industry. With multiple cutting beds operational we ensure lowest lead times ShapeCUT are reshaping the steel, stainless steel and aluminium cutting and profiling industry.

As experts in marine engineering and transport engineering aluminium needs, ShapeCUT’s team is equipped with the knowledge and expertise required to deliver outstanding results that exceed customer expectations.

Custom Fabrication

In the world of architecture, the power of custom steel and aluminium fabrication cannot be overstated. It’s the canvas upon which architects and artists can unleash their creativity and transform abstract ideas into tangible masterpieces. At ShapeCUT, our profile cutting expertise serves as the brush, carving out intricate details and precise forms that bring your artistic visions to life in ways that are both awe-inspiring and functional.

Imagine designing a public square adorned with a captivating steel sculpture that captures the essence of your architectural concept. With custom fabrication, you have the freedom to sculpt steel and aluminium into unique shapes and forms that reflect your vision. Whether it’s a soaring abstract sculpture or a kinetic installation that dances with the wind, the possibilities are limited only by your imagination.

Custom fabrication extends beyond aesthetics; it’s about marrying form and function seamlessly. Architects are increasingly using custom steel and aluminium elements to create functional yet visually striking components within buildings. From intricately designed staircases that are structural marvels to ornate railings that blend safety and elegance, the versatility of custom fabrication allows architects to enhance the overall experience of a space.

ShapeCUT: Your Partner for Success

As you embark on these exciting projects in 2024, ShapeCUT is your trusted partner in steel and aluminium processing. With our state-of-the-art technology, experienced team, and commitment to excellence, we are poised to bring your ideas to life.

Take the First Step Towards New Possibilities. Don’t let this year pass you by without seizing the opportunities in steel and aluminium. To kickstart your journey or discuss your project ideas, reach out to the ShapeCUT sales team today. Our experts are ready to provide guidance, answer your questions, and offer tailor-made solutions to ensure your success in 2024 and beyond.

2024 is your year to shine in the world of steel and aluminium projects. Let ShapeCUT be your partner in shaping a brighter future. Contact us now and let’s make this year a year of possibilities turned into reality!

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

END.

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

©2023 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap